Work with a certified Wisconsin chimney sweep and fireplace repair experts that follows NFPA 211, IRC, and state amendments. Our service includes HEPA-contained cleaning, Level I/II inspections, draft and CO testing under worst-case depressurization, and comprehensive reporting. We specialize in tuckpointing, crowns, waterproofing, liners, safety caps and arrestors, and factory-built system compliance. We set up EPA-certified wood, pellet, and gas units with proper clearances, venting, and permits. Regular service programs maintain safety and efficiency-and continue reading to learn more about our process.

Key Takeaways

- We deliver certified NFPA 211-compliant chimney evaluations, HEPA-certified maintenance, and qualified sweep services adapted to satisfy Wisconsin regulations and routine maintenance needs.

- Comprehensive draft and smoke analysis with precise draft measurements, CO level verification under extreme pressure situations, and airflow balancing procedures for optimal combustion safety.

- Our masonry repair services include, including joint restoration, chimney crown reconstruction, flashing installation and fixes, and moisture protection solutions, all with thorough evaluations meeting code requirements and historically accurate mortar specifications.

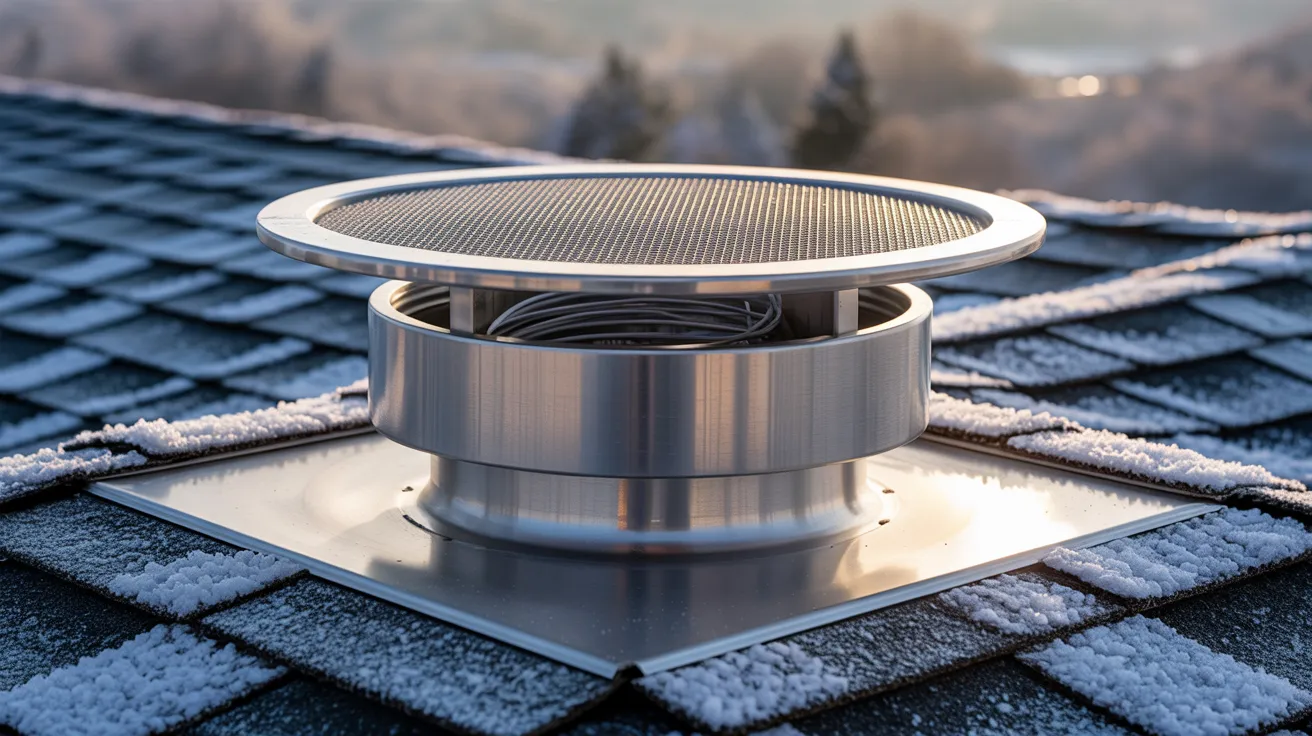

- We install and specify chimney liners, caps, and spark arrestors following UL/NFPA standards, featuring high-quality stainless comprehensive caps and listed factory-built elements.

- We offer stove and fireplace setup and modification services, including required paperwork and comprehensive documentation packages containing visual reports, applicable code references, and certified venting and pressure test documentation.

Comprehensive Chimney Maintenance and Safety Evaluations

Routinely arrange comprehensive chimney cleaning and a NFPA 211-compliant safety assessment to lower fire risk and guarantee proper draft. You'll get measured creosote removal using professional-grade brushes and rotary rods appropriate to your flue dimensions and liner type. We track soot classification, glaze presence, and draft readings, then remove any flue blockages, including nests or masonry debris, using controlled HEPA methods to avoid indoor contamination. We inspect cap, crown, and flashing interfaces without addressing structural rebuilds. Instrumented carbon monoxide testing confirms appliance venting under worst-case depressurization. We assess connectors, thimble seals, and terminations for clearance-to-combustibles compliance. You'll receive burning technique recommendations-fuel moisture targets, load configuration, and air control settings-to minimize creosote buildup. Final reports include images, NFPA 211 checklists, and improvement suggestions.

Brick and Stone Repairs, Tuckpointing, and Restoration

Repair mortar failures, spalled brick, and compromised crowns early to halt water infiltration and maintain structural integrity. You can avoid freeze-thaw damage, chimney movement, and carbon monoxide risk. We inspect masonry according to NFPA 211 and local Wisconsin codes, noting movement issues, salt deposits, and mortar damage.

For mortar restoration work, we expertly coordinate sand gradation, color, and compressive strength, then create properly-sized joint cuts and install appropriate Type N or S mortar, tooling for dense, shed-ready profiles. We swap out deteriorated or shifting brick with compatible replacements, ensuring thorough, fully adhered connections. If chimney crowns show damage, we strip back to solid masonry and install a strengthened, angled crown with expansion joint around the flue.

After heat damage compromises the chimney, we arrange vent relining once we complete masonry stabilization.

Chimney Liners, Caps, and Waterproofing Solutions

You'll evaluate chimney liners for proper dimensions, materials, and UL certification to enhance draft, manage heat, and satisfy NFPA 211 and manufacturer guidelines. You'll pick long-lasting caps-ideally stainless or copper with spark screens and protective mesh-securely anchored to prevent uplift and stop moisture penetration. You'll apply thorough waterproofing by treating crowns, maintaining flashing, and using vapor-permeable masonry coatings to block infiltration without trapping moisture.

The Benefits of Chimney Liners

Installing a chimney liner properly delivers remarkable improvements in safety and performance. The installation safeguards combustibles against high temperatures, controls corrosive elements, and establishes a compliant venting pathway. Proper liner sizing and insulation improve draft consistency, limit condensation, and decrease creosote accumulation-critical elements for preventing fires and maximizing liner durability. You'll also experience enhanced energy efficiency thanks to better temperature maintenance and more efficient burning.

A chimney liner safeguards the masonry from acidic condensate and freeze-thaw damage, maintaining structural soundness. It's necessary when changing fuel appliances, fixing compromised tile liners, or complying with NFPA 211 and manufacturer listings. Code-compliant stainless steel liners endure temperature fluctuations and chimney fires more effectively than unlined systems. With correct installation and yearly maintenance, you'll improve efficiency, reduce maintenance needs, and safeguard indoor air quality.

Selecting Long-Lasting Caps

Following the sizing and insulation of the liner to maintain proper airflow and regulatory standards, protect the upper portion of the system with a robust, listed chimney cap. Opt for stainless covers to guard against corrosion from Wisconsin winter conditions, acidic condensate, and creosote byproducts. Verify UL listing, spark-arrestor capabilities, and compatibility with your fuel type and liner termination. Install a full-coverage cap that deflects precipitation, anchors to the flue or crown firmly, and maintains required free area to eliminate draft restriction.

Use custom mesh sizing to optimize spark management and airflow: 3/4-inch to contain embers as required by regulations, larger only if manufacturer-approved. Include bird and wildlife protection. Opt for removable screens to enable maintenance. Require stainless fasteners and weatherproof seams. Verify bonding/grounding where lightning protection or code compliance is needed.

Key Waterproofing Strategies

Beginning at the crown and extending to the firebox, proper waterproofing starts with a sealed system that blocks liquid water and vapor intrusion while ensuring draft and code compliance. Begin by confirming the chimney liner is intact, certified, and correctly dimensioned; repair compromised flues to meet NFPA 211 and manufacturer specifications. Install a complete cap including mesh and a storm collar to divert water without restricting exhaust.

Safeguard the crown with elastomeric, UV-stable silicone membranes that span cracks and accommodate freeze-thaw movement. For masonry, use breathable sealants that resist bulk water yet enable vapor diffusion, avoiding spalling and efflorescence. Flashing must be counter-flashed and sealed at step joints. Fix mortar joints with Type N or S, then tool for proper compression. Conduct annual inspections and refresh protective layers per product intervals.

Expert Installation and Upgrade Solutions for Fireplaces and Stoves

Upgrade your hearth with systems that meet current codes, enhance efficiency, and focus on safety. You'll receive systems correctly dimensioned to your room load, with setbacks, chimney height, and connector diameters set per NFPA 211 and Wisconsin Uniform Dwelling Code. We evaluate flammable materials, floor protection, and anchoring requirements, then install listed appliances following manufacturer requirements.

Opt for EPA-certified wood, pellet, or gas appliances with sealed combustion. We install stainless steel liners, insulated chimney thimbles, and balanced exhaust systems. Ventilation improvements feature dedicated fresh air intake, make-up air strategies, and mechanical ventilation coordination to maintain proper pressure relationships. Electrical and gas lines are installed with isolation valves, drip legs, and code-compliant GFCI/AFCI safeguards. For fireplace appearance, we recommend noncombustible surrounds, safety-standard mantels, and decorative panels that improve efficiency while ensuring safe clearances.

Addressing Smoke, Draft, and Performance Concerns

Once your new appliance is properly sized and installed according to code, performance depends largely on maintaining draft stability, clean burning, and balanced pressure. Our first step is to verify the flue dimensions, liner condition, and proper chimney height. We then take measurements of draft levels, exhaust temperature, and oxygen content for optimal performance. Should smoke backdraft, we execute draft solutions: addressing thimble and cleanout gaps, optimizing offsets, and improving chimney insulation to boost stack temps.

In indoor settings, we conduct airflow optimization. We test house pressure when exhaust fans are operating, ensure sufficient makeup air, and implement get more info a fresh air intake kit if required. We optimize damper settings, gasket seals, and latch tightness. Finally, we address moisture in fuel, ash layer depth, and baffle alignment to stabilize the burning process and decrease creosote formation.

Regional Requirements, Certifications, and Maintenance Schedules

Be sure to check that your fireplace and exhaust systems adhere to current Wisconsin Fireplace Codes, including requirements for clearances, liner specs, and chimney height standards. Hire technicians who hold Certified Sweep credentials so maintenance, inspections, and repairs adhere to recognized standards and proper procedures. We'll create a yearly maintenance schedule that schedules code-compliant inspections ahead of heating season and post-burn assessments to catch wear, creosote, and safety concerns promptly.

Wisconsin Fireplace Regulations

Although the appearance of fireplaces matters, safety and building codes in Wisconsin must be followed first. It's essential to ensure flues are sized according to appliance specifications, maintain required clearances from combustible materials, and set up appropriate fireproof hearth extensions according to NFPA 211 and Wisconsin Uniform Dwelling Code. Masonry chimneys require lined flues, approved caps, and correctly flashed terminations. Pre-fabricated systems need listed components and manufacturer-specified supports.

Prior to beginning, acquire all local permits and consider permit timelines that differ between municipalities. Keep detailed records of building code adherence with product documentation, visual documentation, and signed pressure and venting tests. Gas log or insert installations must have proper shutoff valves, verification of venting, and carbon monoxide detectors following SPS 321.42. Wood-burning appliances must include spark arrestors and convenient cleanout access. Plan regular preseason inspections, conduct necessary sweeping, and document all findings to streamline insurance, resale, and occupancy certifications.

Accredited Sweep Services

Beyond just the visual aspects, a certified sweep program links your fireplace upkeep to municipal standards, industry qualifications, and a structured maintenance protocol. You get a certified chimney professional who follows NFPA 211, IRC, and Wisconsin amendments for each service. Their thorough sweep training encompasses combustion air, clearances to combustibles, venting geometry, and fuel-specific hazards, so defects aren't missed.

We conduct periodic maintenance checks consisting of: Level I inspection before burning season, interim draft and carbon monoxide assessment, and Level II inspection after the season if needed. We deliver comprehensive photographic reports, building code citations, and a prioritized remediation plan. Our technicians thoroughly inspect chimney components such as caps, liners, dampers, hearth extensions, and smoke chamber integrity; they conduct draft measurements and CO level verification at the heating unit. This detailed reporting facilitates regulatory permits, insurance verification, and property disclosures, guaranteeing your system stays safe, efficient, and regulation-compliant throughout the year.

Frequently Asked Questions

Are Emergency Chimney Services Available Outside Regular Hours?

Indeed, you can access emergency chimney services during nights, weekends, and holidays. We maintain after hours availability with professional experts qualified under NFPA 211 standards. We respond to smoke backup, chimney fires, carbon monoxide concerns, and structural hazards. Expect immediate assistance, remote assessment, and safe temporary stabilization. We maintain detailed records, conduct repairs meeting all regulations or ensure system safety until comprehensive service is scheduled. We'll provide comprehensive safety recommendations and future service planning.

Which Parts of Wisconsin Do You Cover, and Do You Charge Travel Fees?

We provide service to all major Wisconsin regions including Milwaukee, Southern suburbs, Fox Valley, Door County, Northern lakes, and Western Wisconsin. Worried about service availability? You'll get NFPA 211-compliant inspections statewide with documented inspections and draft verification. Service charges are added for areas beyond a 25-mile radius from our hubs; they're flat-rated by zone, disclosed upfront, and waived when full repairs follow a safety inspection. We offer efficient route planning, complete access evaluations, and permit management for code compliance.

Can You Provide Detailed Quotes and Financing Options

We'll send you detailed estimates specifying every aspect from materials and labor to safety requirements and code compliance. All components corresponds to relevant building codes and NFPA 211 standards to ensure full compliance and scope clarity. We offer customizable payment options with upfront deposits, milestone payments, and inspection reserves. You'll receive separate documentation for any changes, permits, and required clearances. You'll need to approve everything in writing before we begin to guarantee clear understanding and safety compliance.

Are Your Field Technicians Insured and Background-Checked?

Absolutely - our technicians are fully vetted and insured. We perform comprehensive background screening prior to employment and conduct regular re-verification. We provide technicians backed by complete liability coverage and workers' compensation insurance for on-site work. We document credentials, maintain training logs, and follow NFPA and local code requirements. You'll receive service reports, job-site hazard assessments, and proof of insurance when needed, delivering secure, accountable, and standards-compliant work throughout the entire service process.

Do You Process Home Insurance for Insurance Claims?

Absolutely. You receive full insurance assistance and claim assistance from first inspection through final repair. We document damage with detailed reports, detailed images, and NFPA 211 references, then collaborate with your adjuster to align scope, estimate, and safety requirements. You authorize all work authorizations. We arrange emergency mitigation, offer permitting support, and maintain chain-of-custody for materials. You receive transparent status notifications, compliant workmanship, and a final closeout package for your insurance provider's records.

Final Thoughts

You opt for clean and clear flues, not hidden creosote; sturdy masonry, not crumbling joints; secure liners and caps, not water intrusion; expert installations, not guesswork; optimal drafts, not smoky rooms. You adhere to NFPA 211, IRC, and local regulations. You arrange seasonal inspections, report findings, and fix defects. You verify clearances, assess draft, and validate CO safety. You protect your home, maintain efficiency, and meet inspection-securely, compliantly, consistently-today, this season, every year.